Characteristics:

■ Large range of 0-30 meters is optional.

■ Protection grade IP67, oil resistance and pollution resistance.

■ Special thread row line structure does not card line does not drop line.

■ Bold steel wire rope is more durable.

■ The linear precision is 0.1% FS.

■ Special appearance port buffer design dustproof collision.

■ The absolute value signal output power-off data without offset.

■ Main body of polar anode alumina shielding surge electrostatic interference.

MPL series rope displacement sensor is a production for mass measuring conditions of displacement sensor, the model using the absolute value encoder effectively guarantee product accuracy and service life, it adopts the special thread line structure, steel wire in the winding wheel groove alone without any superposition, this can make the rope in the winding wheel each circle around the length, not only solved the problem of a large number of range rope displacement sensor poor precision, but also solved the pull rope knot, card, disconnection and other problems. MPL 20 type: 0-20 meter range optional, MPL 25 type: 0-25 meter range optional. MPL 30 model: 0-30 m range is optional. This product can output a variety of analog signals and digital signals, to meet the needs of large travel, high precision and use, suitable for a variety of automatic control applications.

Signal type

Parameter items | digit signal | analog signal |

Measurement length | 0-30000mm is optional | |

Output type | Difference, open circuit, push-pull, RS485 / 232 | 0-5k、0-10k、0-5V、0-10V、4-20mA |

Measuring wheel circumference | 333.33mm | |

Linear precision | 0.05%FS | 0.1%FS |

repeatability precision | 0.01% | |

Maximum reciprocating speed | 3000mm/s | |

Cable length | 2m | |

wirerope | High-flexible inlet wire rope | |

Outline pull | 10N | |

life | 1 million to two million times | |

working voltage | DC5V,DC24V, DC10-30V | DC12V, DC24V |

working temperature | -25—85℃ | -45—125℃ |

levels of protection | IP65 | |

Case material | Imported aluminum alloy, the surface of the anti-static interference is not conductive | |

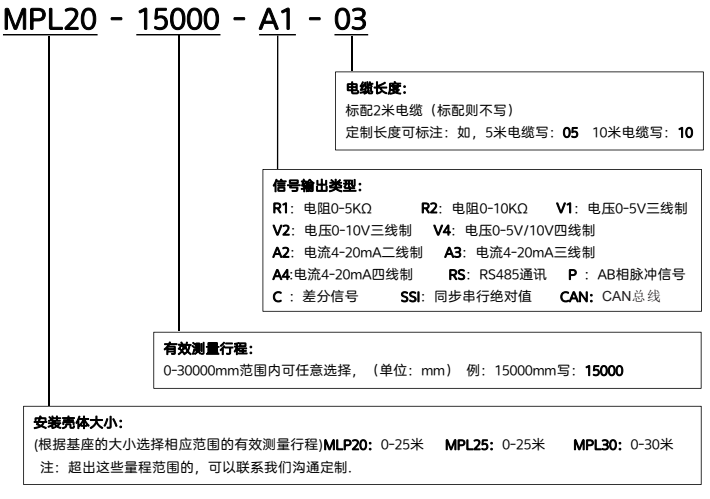

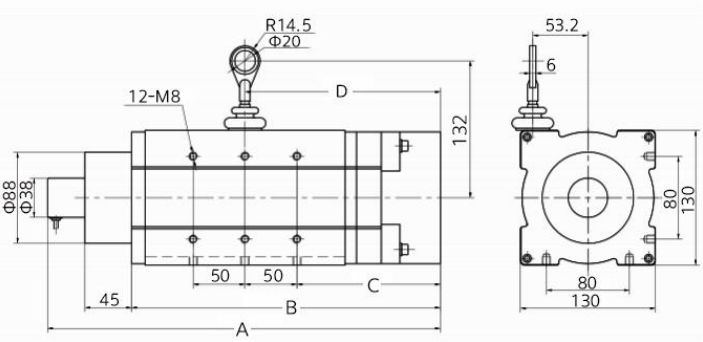

● MPL Dimension Diagram:

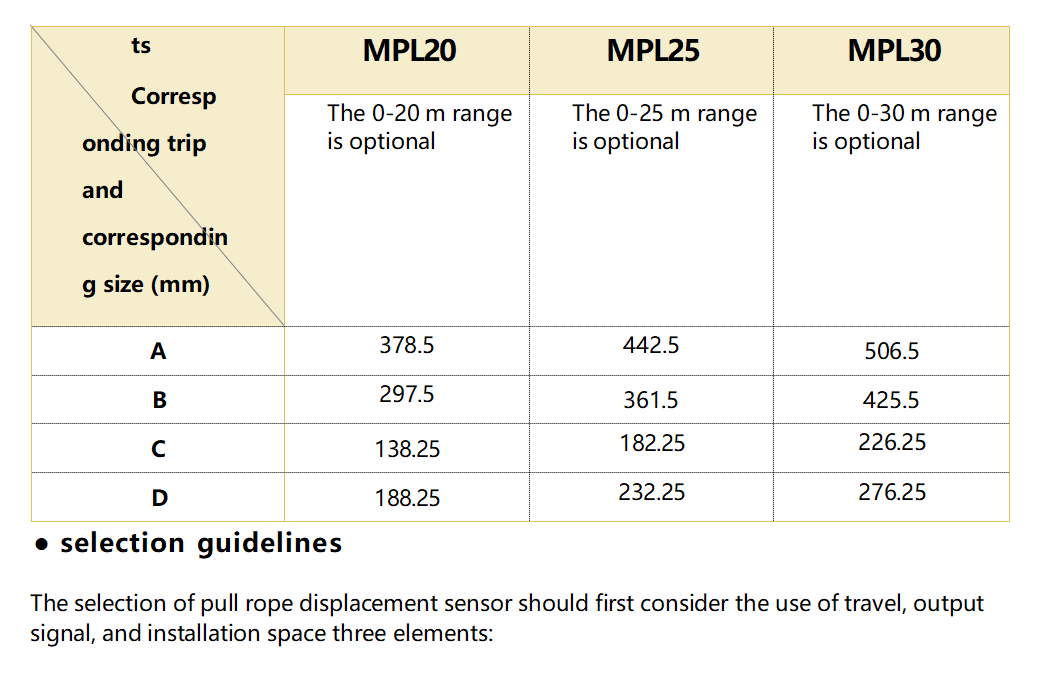

The size of MPL series will change due to the selection of range. The variable size of the drawing will be replaced by the code of letters. Please confirm the corresponding size length according to the required range. The parameters are as follows:

1. When choosing the sensor range, it is recommended to leave a margin, (the sensor range is larger than the actual travel size) it is strictly prohibited to exceed the travel range.

2. The sensor signal output type should match the signal type that can be collected by the field acquisition equipment.

3. Site installation space should be considered, and the drawline displacement sensor suitable for size and installation form should be selected.

4. If you have questions about the selection, you can contact our account manager for detailed consultation.

● Applied range:

Mainly suitable for: storage location positioning, reservoir dam protection, gate opening control, pressure machinery, papermaking machinery, textile machinery, metal sheet machinery, packaging machinery, printing machinery, horizontal controller, construction machinery, industrial robot, shooting machine, woodworking machinery, elevator, air compressor, oil press, height machine, X-Y axis and other length displacement, liquid level measurement and other automatic measurement occasions.

1. Use the four fixed screw holes at the bottom, and directly install or protect or other machinery according to the site and machine installation space facilities.2. When installing the stainless steel cable, pay attention to the horizontal Angle, which means that the steel cable from the outlet to the moving part of the horizontal sliding position, keep the minimum Angle (5°), to ensure the measurement accuracy and the life of the steel cable.

3. A layer of nylon (nlon) outside the cable body, do not let it cut, burn, impact and other improper things by external forces; excessive powder dust, debris or enough to destroy the cable stay in the internal pulley or outlet will cause the cable damage, resulting in poor operation failure.4. Before being installed on the workbench or fixed seat, do not pull the steel cable out by hand or other products and let it bounce back instantly. This move will cause steel cable fracture, damage to the body structure and personnel safety.

5. MPL series: the instantaneous acceleration of the movement should not exceed 3 meters / second, if the cable fracture or personal loss caused by the lifting.

6. If used in a non-linear movement mechanism, please install the appropriate pulley operation.

7. If it is used in a harsh environment or on special occasions, please install the protective device by yourself or talk with the engineering department and distributor of the company. Otherwise, the company shall not be responsible for the damage caused to the products.