Characteristics:

■ German technology, precision structure.

■ Absolute position output, no zero.

■ Imported steel wire rope and precision bearings.

■ High linear accuracy, strong anti-interference ability.

■ High life life, suitable for complex environment operations.

WEP series pull rope displacement sensor is a precision sensor produced by German technology. Its special winding structure and precision bearing ensure the life and precision of the product. WEP 50 series: 0-1000mm range is optional. WEP 70:750-1250MM range optional, WEP 90 series 1500-5000mm range optional. This series of products adopts internal and external double-layer shielding and circuit filtering processing technology, so that the sensor output of the analog signal has a longer transmission distance and stronger anti-interference ability in similar products, is a high-end displacement sensor product that can adapt to the complex working environment.

Technical parameters | |||

model | WEP50/70/90-R | WEP50/70/90-A1/V1/V2 | |

output signal | Precision potentiometer 0-5 Kohm | ||

working voltage | max.24V DC | ||

working temperature | -10~+100℃ | ||

storage temperature | -20~+120℃ | ||

Sensor element | Precision wire around the conductive plastic hybrid potentiometer | ||

Measurement length | 100/200/250/300/500/1000mm | ||

levels of protection | IP67 | ||

The reciprocating speed | 0.5M / s | ||

Linear precision | 0.05%F.S | ||

repeatability precision | 0.01%F.S | ||

resolution | No-break resolution infinite | ||

wiring | 1 meter cable or M12 four needles (buy) | ||

Model Description: WEP 50-1000-R-F | |||

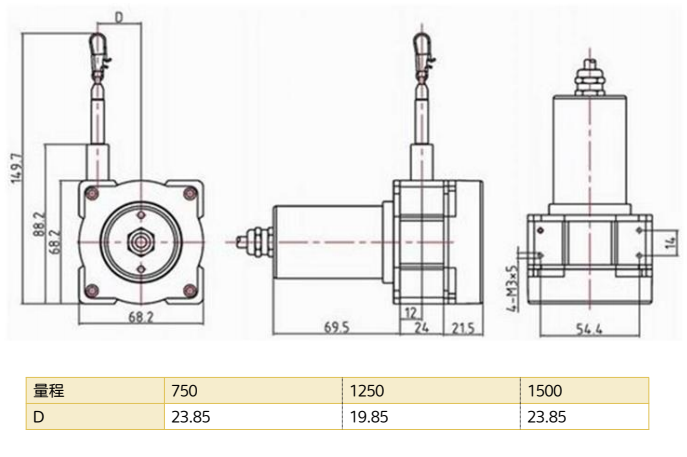

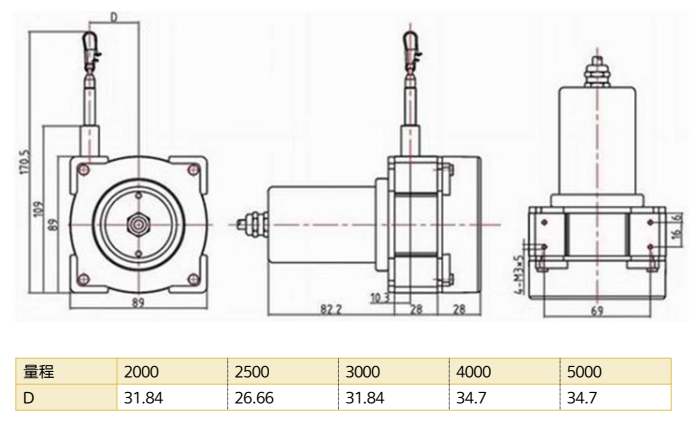

WEP50:(100/200/250/300/500 / 1000mm) is optional WEP 70: (750 / 100 / 1250MM) is availableselect WEP90:(1500/2000/2500/300 0 / 4000 / 5000MM) is optional | -1000 | (-R) | (-F) |

The measurement range is 0-1000m m | Output signal: potentiometer 0-5K | Long-life span: 8 million times | |

The 0-5 meters specified specifications are optional | A1:4-20mAV1:0-10V V2:0-5V | Standard: 5 million times | |

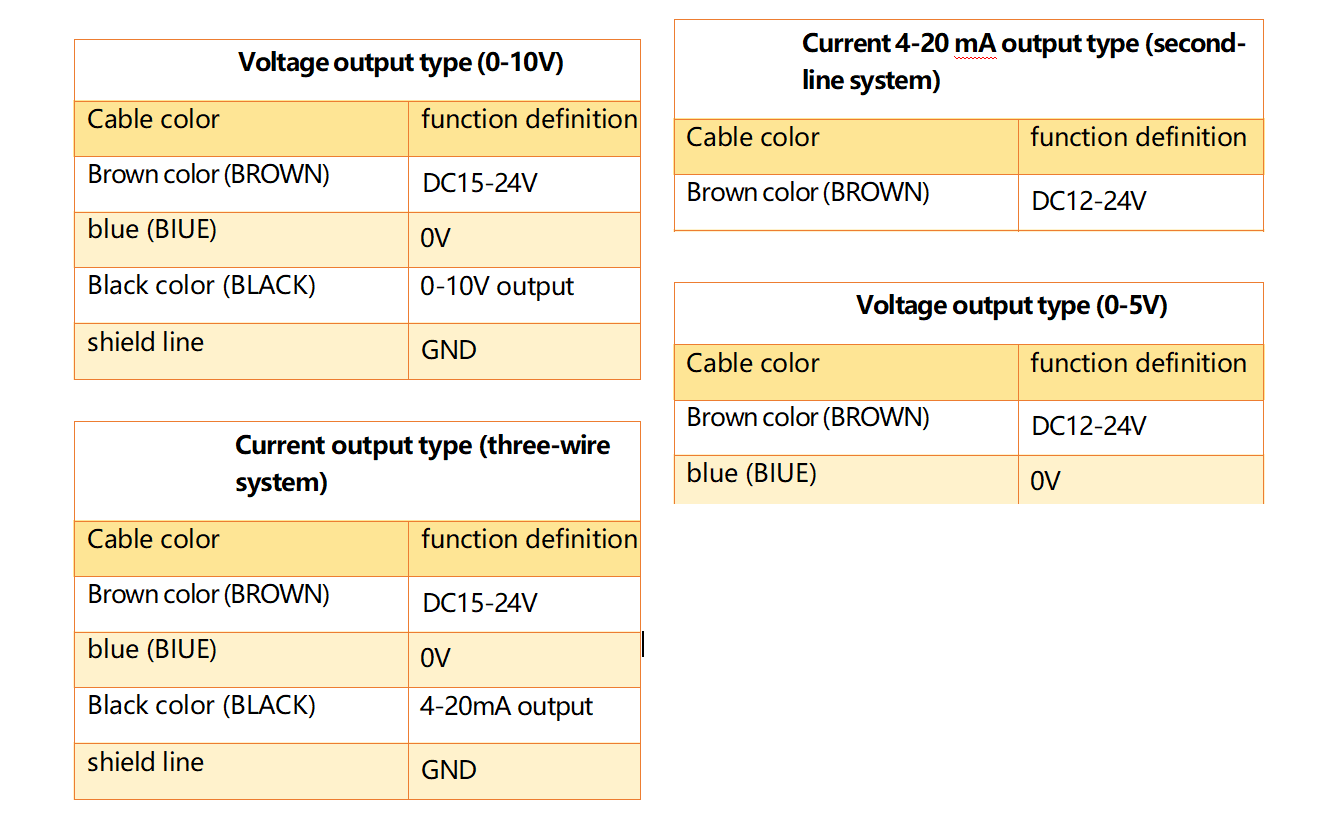

● Wiring definition:

1. Using the four fixed screw holes at the bottom, the site and the machine installation space facilities need to be installed directly or protected or other machinery.

2. stainless steel cable installation, must pay attention to the horizontal Angle, that means to try to make the steel cable from the outlet to the moving part of the mechanism, at the work of horizontal sliding, maintain the minimum Angle (allowable deviation of 5°), to ensure the measurement accuracy and the life of the steel cable.

3. A layer of nylon (nylon) outside the cable body, do not let its cut, burn, impact and other improper things caused by external forces; excessive powder dust, debris or things enough to damage the cable in the inner pulley or outlet will cause cable damage, resulting in poor operation block.

4. If not installed on the workbench or fixed seat, do not pull the cable out by hand or other products and let it bounce back instantly. This move will cause steel cable fracture, damage to the body structure and personnel safety.

5. The instant acceleration of WEP 50 series must not exceed 0.5 m / s: The instant acceleration of WEP 70 / 90 series must not exceed 0.8 m / s. The company shall not be responsible for the fracture or personal loss caused by the steel cable.

6. If used in a non-linear motion mechanism, please install the appropriate pulley for operation.

7. If it is used in a harsh environment or on special occasions, please install the protective device by yourself or talk with the engineering department and distributor of the company. Otherwise, if because

The company shall not be responsible for the damage caused to the products.